Silicon Simplified

Silicon nanowire-infused (SiNW) graphite is the centerpiece of SINANODE’s Silicon Technology Platform which also includes a fully developed manufacturing process/scale-up plan and flexible cell design options. SINANODE delivers:

- Tripled energy capacity of the anode

- Faster charging speeds

- Greater power

- Reduced graphite

- Lower cost per kWh

- Reduced carbon footprint

Silicon can store ten times the energy of graphite alone yet previous attempts to include more silicon in the anode faced challenges of silicon expansion and breakage. This limited the amount used to extremely small percentages and only modest performance improvements. Being able to add larger amounts of silicon—efficiently—is the essential breakthrough needed to produce competitive EVs that meet market demand for high-performance, affordable vehicles.

SINANODE silicon nanowire technology is the only silicon solution that meets the technical and economic challenges.

SINANODE

[ sin' · an · node ]

The name for SINANODE is an amalgamation of three words describing the makeup of our technology.

Si

Silicon

Nano

Scale

Anode

Electrode

The SINANODE Step

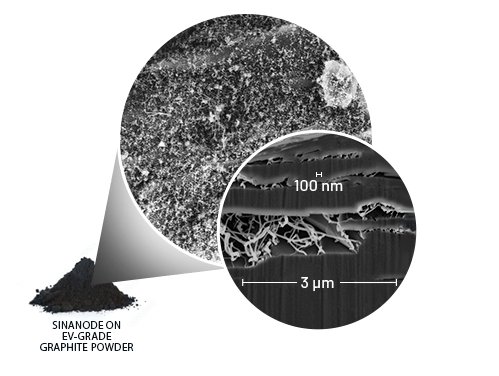

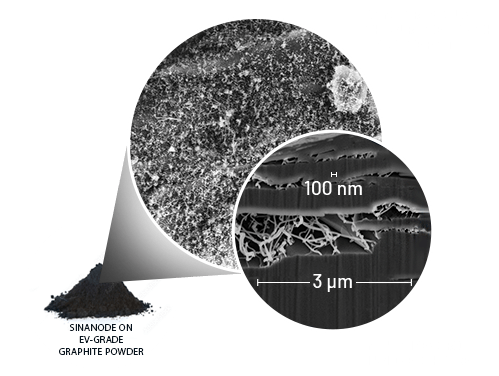

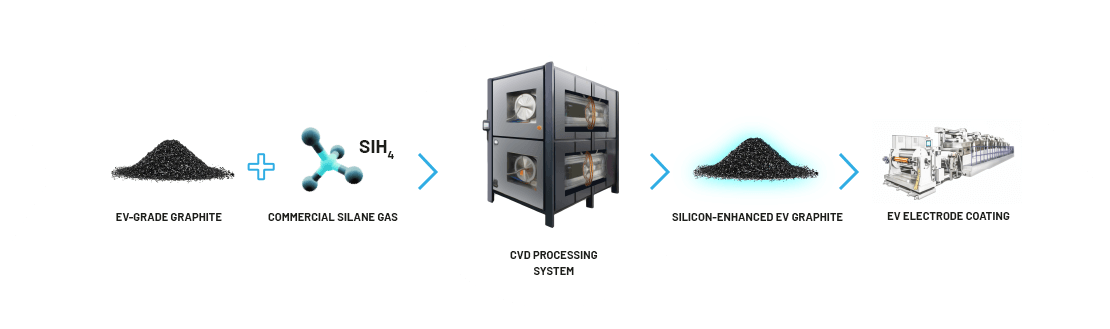

The SINANODE Step infuses silicon nanowires into EV-grade graphite using existing CVD machinery. This makes the silicon directly accessible to lithium ions without the inefficiencies of trapping silicon inside inactive carbon. SINANODE delivers 3,250 mAh/g—the highest of any silicon solution. This means higher energy density and greater EV range.

Silicon nanowires are electrical wires orders of magnitude smaller than human hair. Using only silane (a gas produced from metallurgical-grade silicon and available from multiple suppliers), nitrogen, and modest amounts of electricity, the SINANODE process infuses silicon nanowires directly into the graphite, much like plugging an electrical cord into an outlet. When charged, silicon nanowires remain pliant and do not crack. With hundreds of thousands of wires on each graphite particle, the silicon triples the energy density of the anode.

- Nanowires cover the surface and fill the pores

- Low surface area

- Electrically connected

- No inactive materials

The Only Technology Fusing Nano-Silicon Into Commercial Graphites

How does

SINANODE work?

This technical video demonstrates how SINANODE solves the issues that plagued previous silicon solutions.

Production Technologies

The Sinanode Step

Designed for EV Scale at Lowest Cost < $2 per

kWh of Silicon Capacity

Electrode & Cell Design

With less polymer and uniformly attached silicon, SINANODE enables dry electrode coating and similar new electrode manufacturing processes. This means about $1B of Cap Ex saving per EV cell factory.